Insights

WESTBOROUGH, Mass., Merchants Fabrication, Inc. (MFI), a full-service metal plate and structural shape manufacturer specializing in the machine building industry, has relocated from their previous … Continue reading Merchants Fabrication Inc. Makes the Move to Westborough

SOUTHBRIDGE, Mass., Merchants Fabrication, Inc. (MFI), a full-service metal plate and structural shape manufacturer specializing in the machine building industry, is pleased to announce that … Continue reading Announcing New Production Supervisor

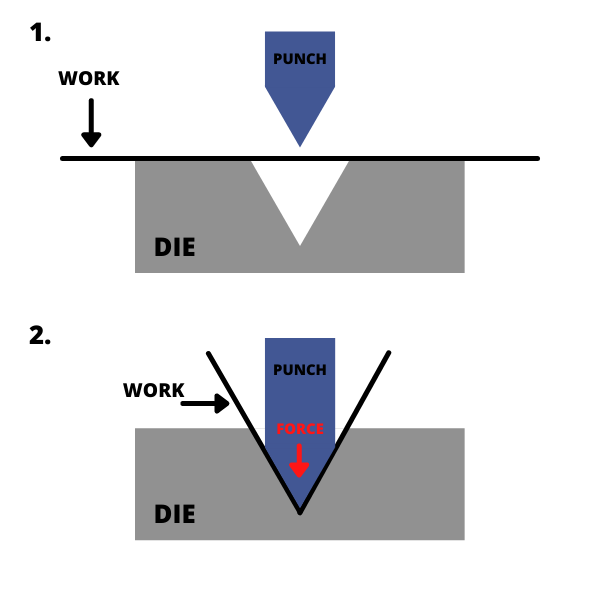

In the metal fabrication industry, metal bending is one of the most common metal forming processes. Metal bending, also known as press braking, flanging, and … Continue reading Let’s Get Bendy

As an entrepreneur, when you have a great idea for a product or service, one of the first things you do is surround yourself with … Continue reading Truly Made in the USA: How US Manufacturers Work Together

If you or your business are in the market for metal signage, there are a few things to consider before getting started. What is the … Continue reading Sheet Metal Signage: Beautiful and Durable

Art, by definition, is an expression of human creativity and imagination. It can present itself in numerous forms; from painting and graphic design to pottery … Continue reading 11 Cool Welding Projects

SOUTHBRIDGE, Mass., Merchants Fabrication, Inc. (MFI), a full-service metal plate and structural shape manufacturer specializing in the machine building industry, is pleased to announce that … Continue reading Under New Management

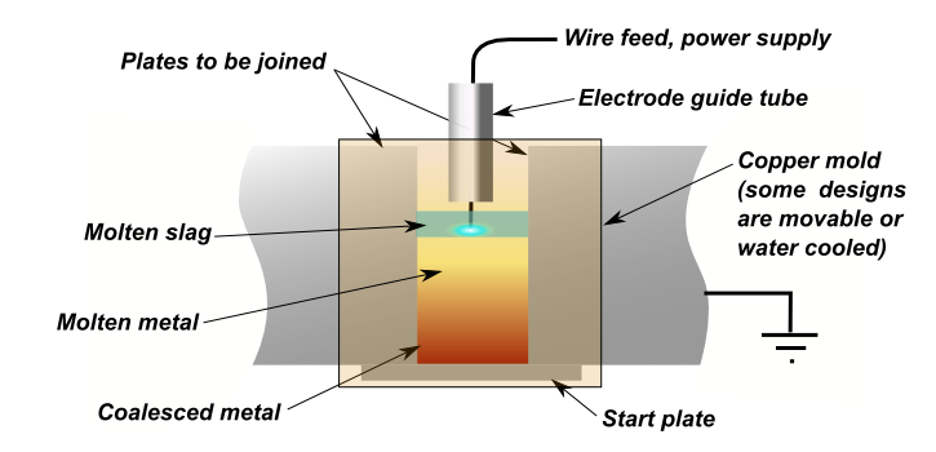

In the late 1930’s, electro-slag welding (ESW) process was first created in the United States then patented by Robert Hopkins in 1940. The E.O. Paton … Continue reading Electro-slag Welding 101

Tolerance is a word that is tossed around a lot in the welding world and it stands as the most analyzed element for evaluating manufacturing … Continue reading Tolerance – Why It’s Important

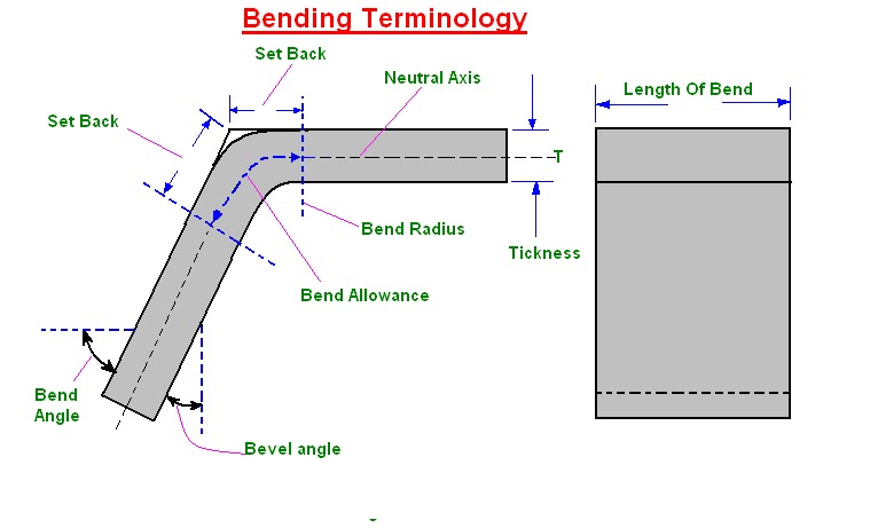

Welding procedures require bend tests for many parts such as tubes or pipes. It’s important to know the properties of the part to be worked … Continue reading Understanding Bend Tests & Radius

Featured Project

-

MFI fabricated this stainless vacuum manifold for a commercial client whose business manufactures beer canning equipment.

MFI fabricated this stainless vacuum manifold for a commercial client whose business manufactures beer canning equipment.