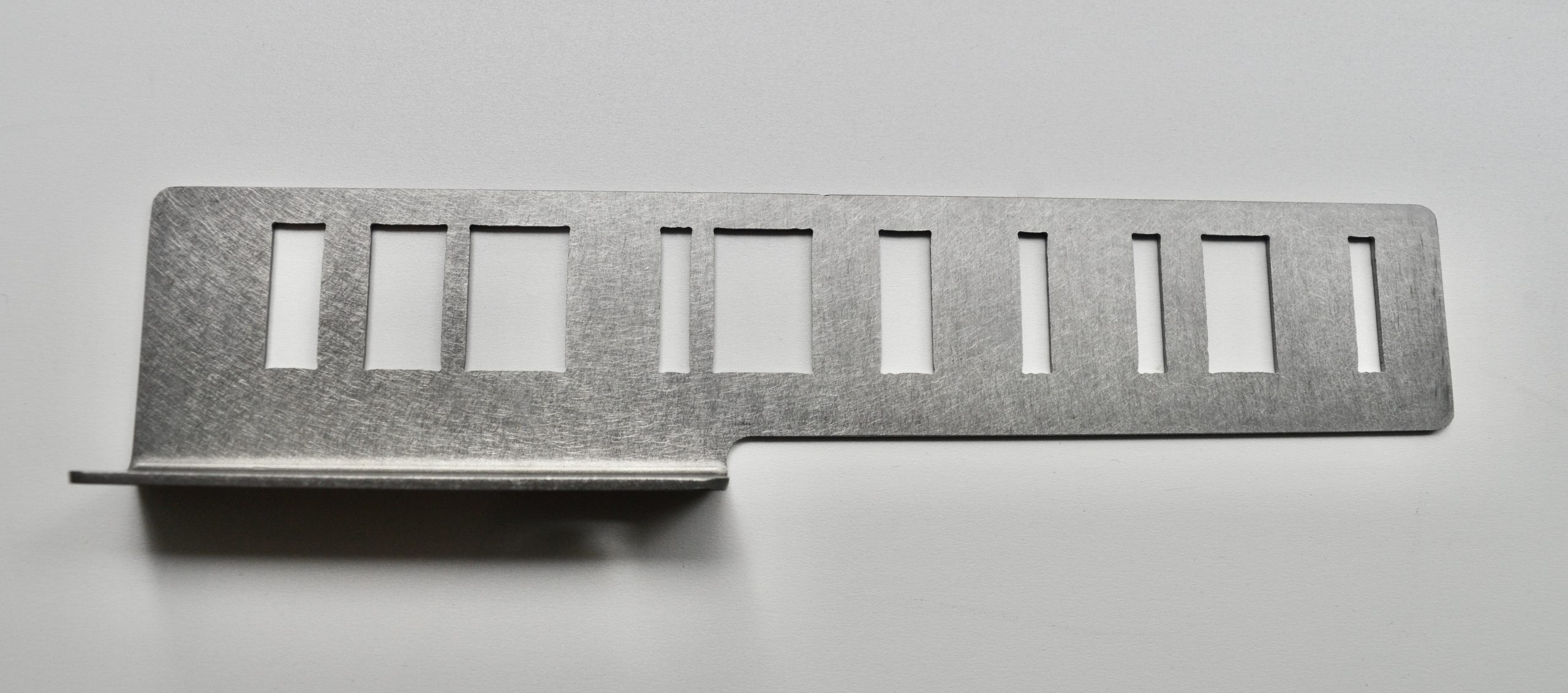

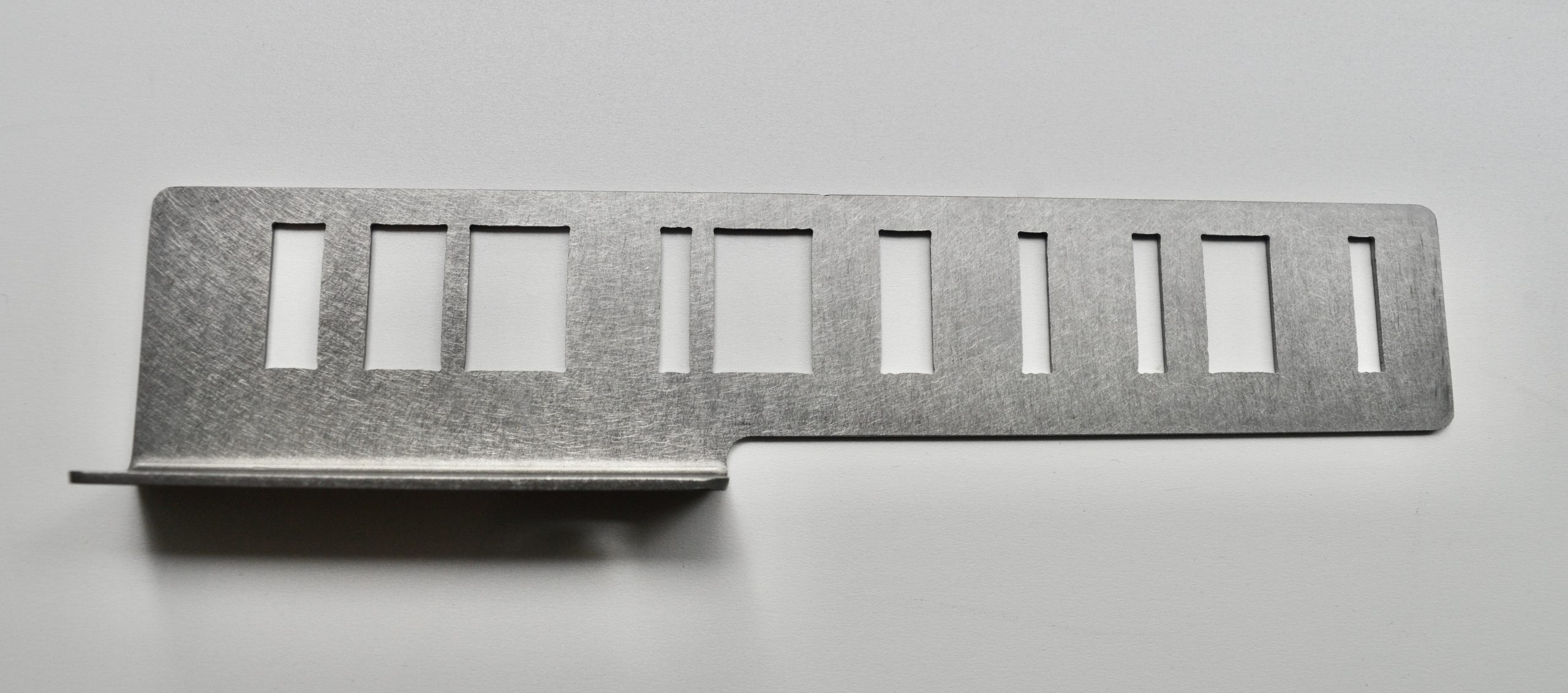

Stainless Steel Codeplate

MFI fabricated this stainless steel codeplate for a commercial customer to assist with verifying product locations in warehouses.

MFI fabricated this stainless steel codeplate for a commercial customer to assist with verifying product locations in warehouses.

MFI fabricated these conveyors for a manufacturer of plastic blow molding systems, with whom MFI has a longstanding relationship.

MFI partnered with a manufacturer to engineer and fabricate this custom stand for use with large air systems in centralized destruction facilities.

MFI fabricated this custom sort table for a manufacturer that supplies security products to the federal government.

MFI fabricated these specialty parts for a hard drive crusher housing for a manufacturer of data destruction devices.